Product

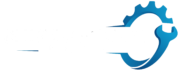

Machining with assembly

Machining with assembly refers to the process of manufacturing parts or components through machining operations and then assembling them into a final product.

The designed parts are manufactured using machining processes such as milling, turning, drilling, grinding, or additive manufacturing techniques. These processes shape the raw material into the desired form with high precision.

Once the individual parts are machined and inspected, they are assembled into the final product. This assembly process may involve various techniques such as welding, fastening (using screws, bolts, or adhesives), or press-fitting depending on the design and material properties.

Fabrication with Machining

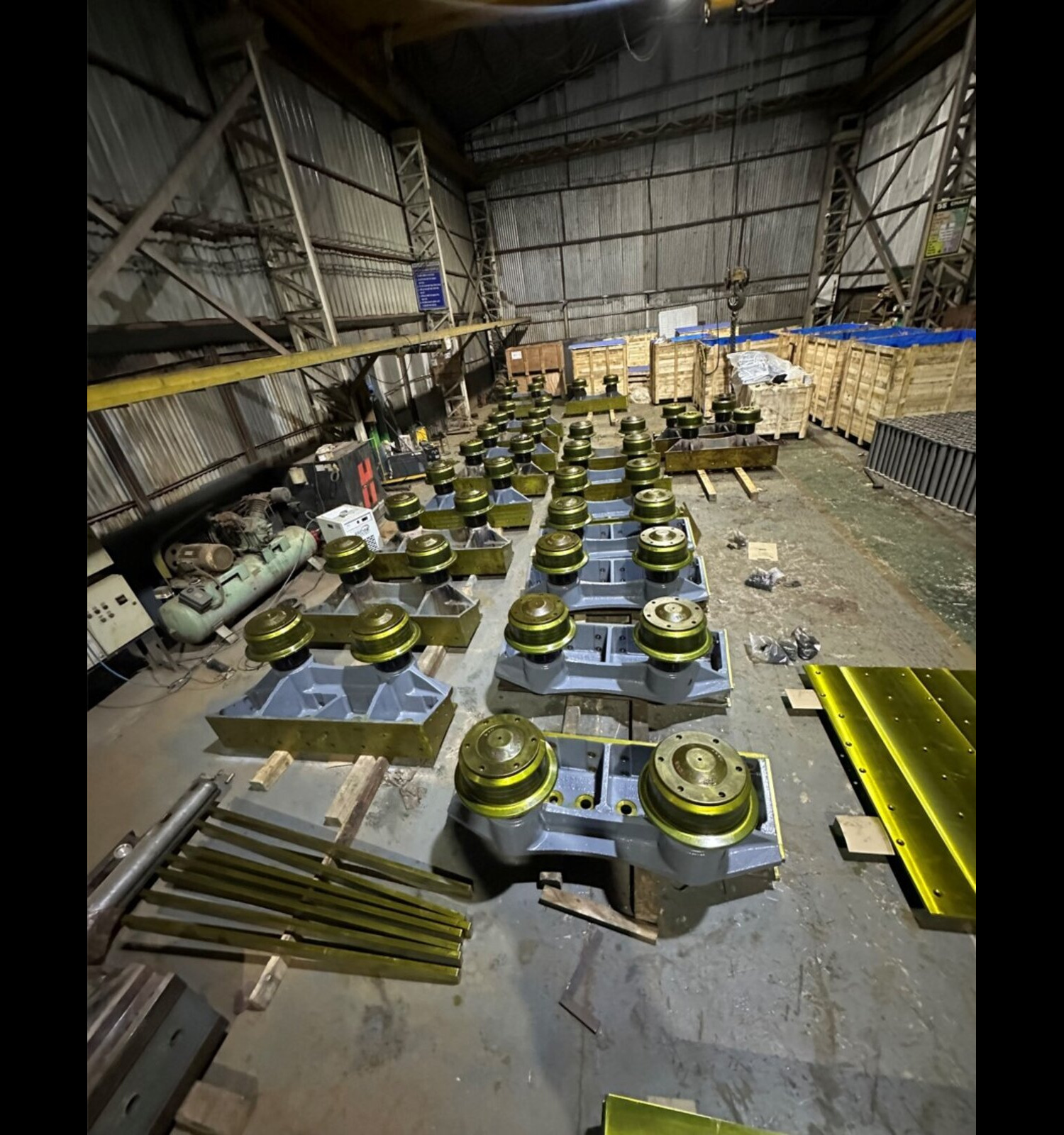

We SGEW procure Forgings & Castings with special grades to manufacture above Industries equipment’s. We provide drawings to procure forging material from our vendors & take them in as Raw condition as per our sizes than we perform all Laboratory tests (Non-Destructive Tests) to ensure material quality for performance & equipment Life Than we mount equipment on our CNC Horizontal boring & milling machine to machine equipment as per Drawing. After machining we perform customer inspection process & apply rust preventive oil for better life of equipment.

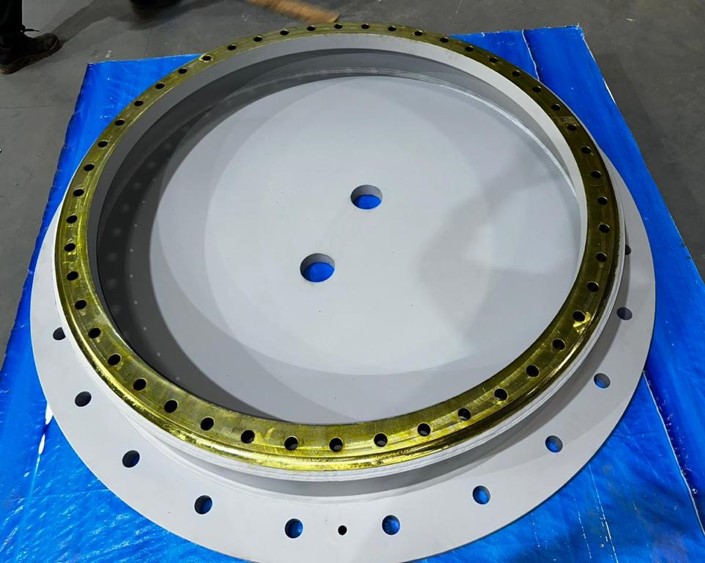

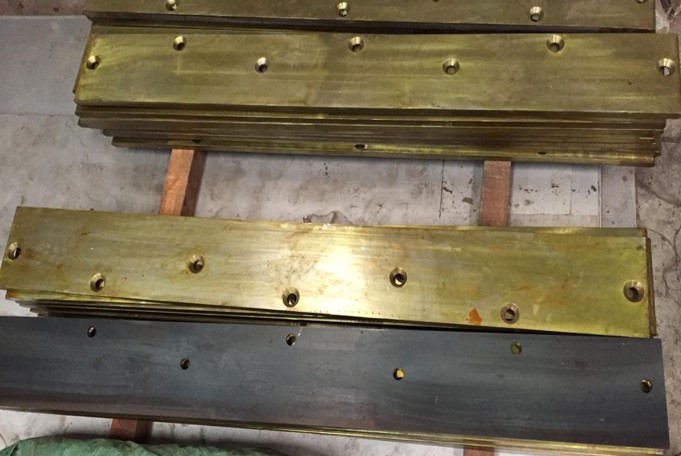

Machined jobs

We SGEW procure Steel Raw plates with special grades to manufacture above Industries Equipment’s. We take plates cut to required sizes as per drawing. Than we bend material, drill holes in material, make fitting as per drawing equipment, and then we do welding to special material as per welding process as per American standards. After welding we clean surface material by Sand Blasting Process & paint material as per required specification from customer. After final component /Equipment is ready we perform Customer Inspection & dispatch material to customer.

Special material fabrication

We SGEW procure Forgings & Castings with special grades to manufacture above Industries equipment’s. We provide drawings to procure forging material from our vendors & take them in as Raw condition as per our sizes than we perform all Laboratory tests (Non-Destructive Tests) to ensure material quality for performance & equipment Life Than we mount equipment on our CNC Horizontal boring & milling machine to machine equipment as per Drawing. After machining we perform customer inspection process & apply rust preventive oil for better life of equipment.